Leaky valves found in industrial plants can cause tremendous damage, posing a major safety risk. Therefore, it is essential to inspect valves regularly and maintain them properly to help ensure their proper functionality. This will be helped by the VALVE SENSE inspection system, which was developed in cooperation between our German partner i.Safe MOBILE and Austrian manufacturer Senseven. The system is also available to Polish entrepreneurs. How does it work?

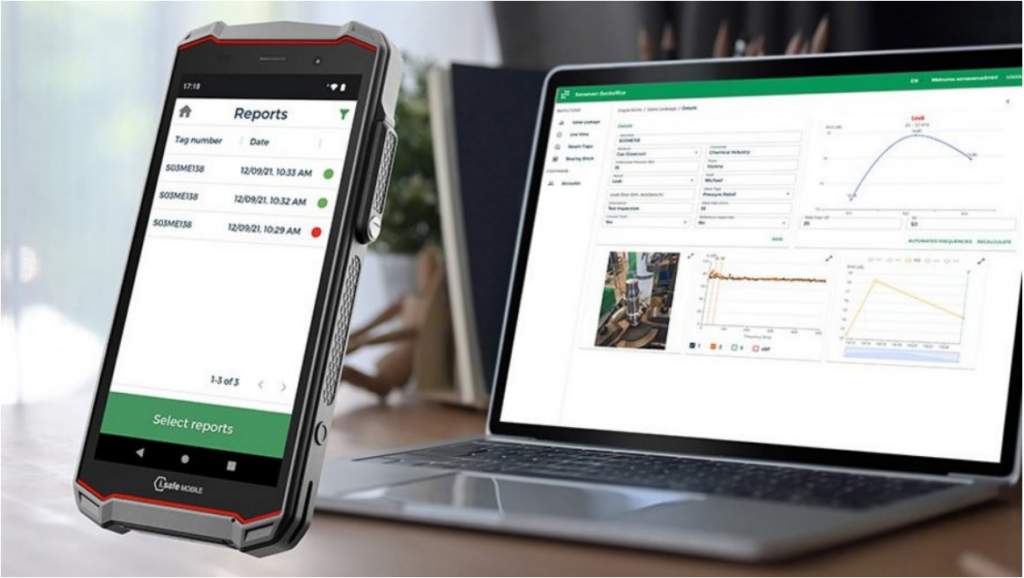

The Valve Sense system works through powerful software and artificial intelligence support. It is based on the proven acoustic emission method and combines it with new digital functions. High-quality acoustic emission sensors are connected to a 5G IS540.1 smartphone and a specially developed app.

When a valve leaks, energy is released that emits high-frequency acoustic signals. It is these signals that are detected by the Valve Sense system’s acoustic emission detector. In turn, they are then sent to the IS540.1 smartphone and processed.

Importantly, the Sensevens app assists the system user in such a way that all inspection activities are carried out as part of the current technological process. In this case, specialized knowledge in this area is also not necessary.

The main benefits that VALVE SENSE system owners receive include:

- No need for time-consuming employee training. No specialized knowledge is required to use the system. The system guides the user step by step, thanks to an easy-to-use and user-friendly application interface.

- Support of algorithms and artificial intelligence. The algorithms and artificial intelligence functions used automatically analyze sensor signals and provide immediate results.

- Immediate leak detection. In industry, especially manufacturing, every minute is literally at a premium. Therefore, the sooner an abnormality is detected, the faster the ability to react and prevent unwanted consequences.

- Regular inspection. Users of the system can monitor the condition of the valves in operation on an ongoing basis and react in a timely manner to any irregularities.

- Taking measurements is possible during the ongoing production process. There is no need to test the performance of the valve at an external diagnostic station. This avoids production downtime and at the same time provides significant time and cost savings.

The data obtained with the system is automatically saved on a cloud-based platform (back office), allowing it to be used for further analysis and report generation. No Internet connection is required to perform the inspection. Automatic synchronization of data will take place immediately, as soon as the smartphone accesses the network. In this way, the “cloud” becomes a place where maintenance personnel can get an overview of all critical valves and identify needs for appropriate action.

HOW IT WORKS – VALVE SENSE SYSTEM STEP BY STEP

Identify the valve

Scan an RFID tag, QR code or enter a valve’s serial number using the touch screen.

Detect acoustic emission signals

The software will easily guide you through the entire process. Step by step you will see where to measure: directly in front of the valve – directly on the valve – directly behind the valve.

Presentation of results

By using acoustic emission signals, the algorithms automatically detect whether the valve is tight or not.

Automatic report generation

Data synchronizes automatically in the back office system to determine maintenance activities based on relevant reports.

Want to know more about the system and devices that will improve your plant’s communication security and analytics? Be sure to contact our experts, who will advise you on which system will work best for you. Call 32 255 53 53 or write to biuro@ex-mobile.tech

There are no comments